In alignment with the Chinese Academy of Sciences' (CAS) 'Four Firsts' and 'Three Orientations' principles, ZHGAS undertook the 2017 CAS Key Program for Transformative Technological Achievements ('Hongguang Initiative'). As the industrialization platform for this initiative, the Circulating Fluidized Bed Coal Gasification Technology has facilitated the commercialization of research outcomes, achieving extensive market influence.

CGAS Technology: Narrating China's Clean Coal Journey

As lump coal prices soared to ¥1,000 per ton, Fan Fei, General Manager of Lanzhou LS Gasification Technology Co., Ltd. in Jinchang, Gansu, felt secretly relieved: 'Had we not adopted the Chinese Academy of Sciences' innovative technology, our coal gasification operations would likely have become unsustainable.

In late September, the new project commenced operations. With technological upgrades and reduced costs, downstream enterprises—once struggling to survive—finally gained the opportunity to reverse losses and overcome operational crises.

Similarly betting on this technology was Guizhou Anshun Hongsheng Chemical Co., Ltd. General Manager Sun Xiangming informed the China Science Daily: 'With lump coal prices soaring and environmental standards escalating, we had no retreat. Yet adopting foreign technologies required a staggering 400–500 million yuan in retrofitting costs. At this critical juncture, learning that CAS's technology required only 100 million yuan, we proactively sought this solution.

This game-changing technology—acting as an industrial lifeline—is the Circulating Fluidized Bed Coal Gasification (CGAS) technology developed by the Institute of Engineering Thermophysics, Chinese Academy of Sciences (hereinafter referred to as 'IET-CAS').

Empowering Chinese Coal on a Grander Stage

Jinchang, Gansu—located in the Hexi Corridor—evolved into a resource-based industrial city following the discovery of nickel deposits. In recent years, Jinchang has accelerated the transformation of traditional industries through high-end upgrades, low-carbon transitions, and intelligent retrofits. The 2015 surge in lump coal prices pushed coal chemical enterprises to the brink of viability, further underscoring the imperative for industrial upgrading.

At this critical juncture in 2016, the 1,000-ton circulating fluidized bed pressurized coal gasification demonstration project landed as a key investment initiative in Jinchang City. Jointly developed by Lanzhou LS Group and the Institute of Engineering Thermophysics, it replaced high-pollution, high-cost fixed-bed gasification technology with low-pollution, cost-efficient circulating fluidized bed (CFB) solutions.

Unexpectedly, upon project completion, an unforeseen challenge arose: due to national policy adjustments, the initially planned Xinjiang Guanghui coal became unavailable, forcing a switch to local low-rank pulverized coal with ash content surging from 15% to 25%.While this left the enterprise scrambling, the technical team from the Institute of Engineering Thermophysics remained unflappable.'CGAS technology boasts exceptional fuel flexibility—its greatest strength is not being picky about coal types,' Zhu Zhiping, a researcher at the institute, told China Science Daily. 'Switching coal types only requires recalibrating calculations and adjusting operational parameters. No matter how the source fluctuates, we ensure downstream stability.

Project leader LV Qinggang, Director of the Circulating Fluidized Bed Laboratory at the Institute of Engineering Thermophysics, stated: 'We can efficiently process coals with high ash, high melting points, or high moisture—types that conventional technologies either fail or perform poorly in gasifying.Such confidence stems from technological supremacy.

China's coal reserves are complex and diverse, with 55% classified as low-rank pulverized coal—traditionally deemed 'unusable' due to poor reactivity. Conventional wisdom held that only high-reactivity coals suited gasification, leaving low-rank pulverized coal out of the equation.Yet the Circulating Fluidized Bed Laboratory challenged this paradigm. They argued that low-rank pulverized coal—abundant and widely distributed—should not be 'sentenced to death' on scientific or technical grounds.

Targeting this goal, the lab spent over a decade breaking through technological barriers. Today, CGAS technology handles Xinjiang’s high-alkali coal, Guizhou’s high-ash coal, and even Indonesia’s high-moisture lignite. This capability alone slashes operational costs by more than one-third.

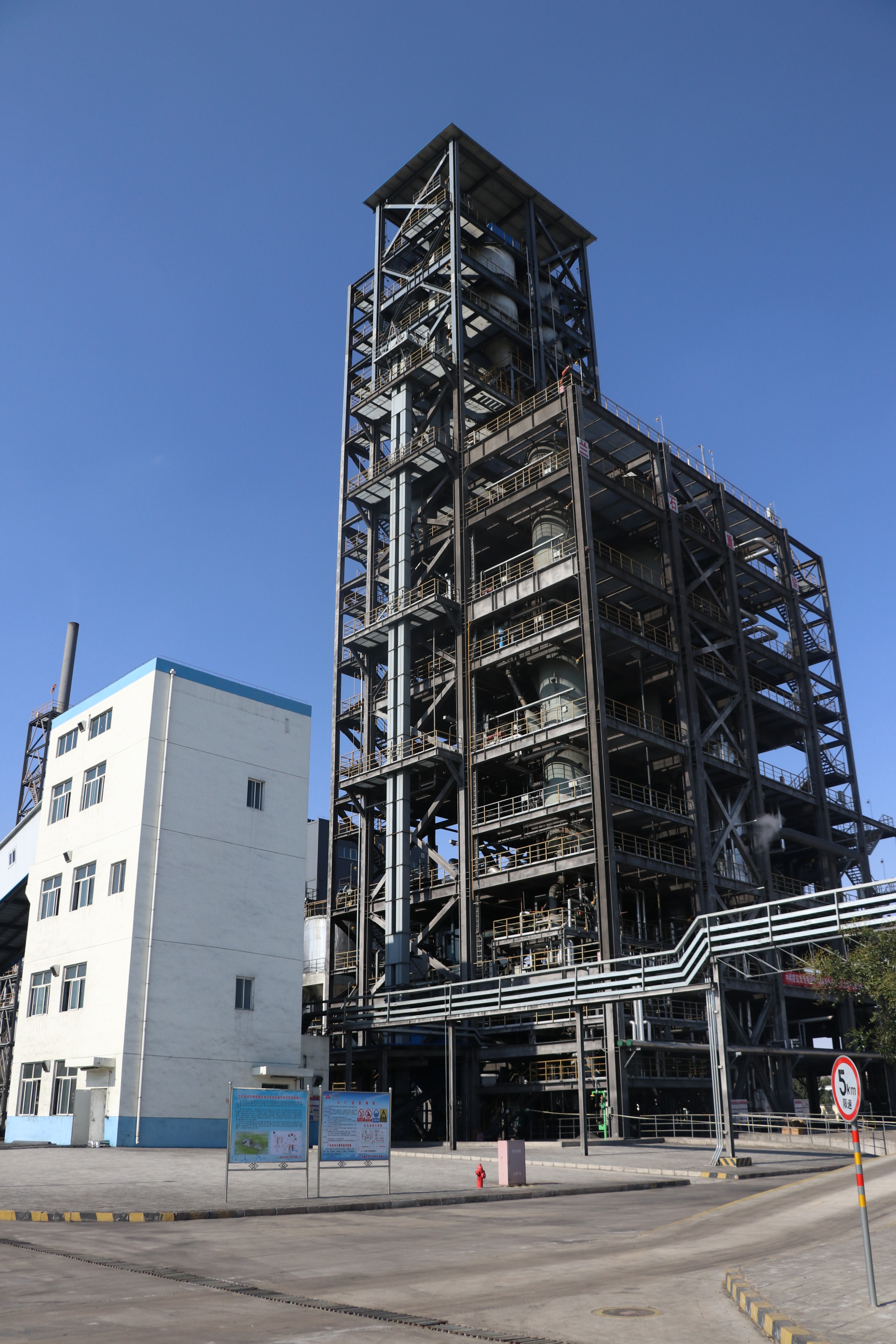

In early autumn, our visit to the project site at the Hexi Fort Chemical Industrial Park in Jinchang revealed a striking contrast to traditional gasification plants. Instead of chaotic scenes, we found a clean, orderly facility—with only the hum of pumps and fans signaling its operation.

'The system’s fuel adaptability has exceeded design specifications,' remarked Fan Fei, visibly relieved.

As China’s first pressurized circulating fluidized bed gasification system, it achieves full automation, reduces water consumption by 30%, and eliminates phenolic wastewater (nearly 100,000 tons annually). The project cuts enterprise costs by approximately ¥50 million yearly while delivering significant environmental benefits.

A decade honing one sword

The secret to handling complex and variable coal types lies in the concept of "circulation".

Circulating fluidized bed" refers to establishing large-scale solids circulation within the system, ensuring the gasifier maintains high-density solid materials to enable efficient gasification reactions. According to technical specifications, the CGAS system operates at a material circulation ratio of 60–100 times. This means that for every 1 ton of coal fed into the system, at least 60 tons of solid materials are circulating and reacting.

Achieving such high-efficiency circulation requires seamless integration of all components. As Zhu Zhiping emphasized: "The circulating fluidized bed is a systems engineering endeavor.

The CGAS system comprises a gasifier, cyclone separator, and return feeder. Once operational, the entire loop operates under high-temperature and high-pressure conditions, maintaining continuous operation at 1,000°C for over a year. With no mechanical rotating components inside, regulation relies entirely on operational parameters. After high-temperature syngas production, downstream processes include waste heat recovery, baghouse filtration, and fly ash vitrification. Failure in any segment can halt the entire project. Such formidable challenges make it a daunting prospect for technological imitators.

Atmospheric fixed-bed gasification technology, characterized by small scale, low automation, and severe pollution, faces explicit national bans on new installations for certain furnace types. As Lü Qinggang emphasized, the market urgently demands gasification technologies with three critical attributes: strong coal adaptability, clean and efficient operation, and low cost.

Targeting these goals, the Circulating Fluidized Bed Laboratory (established in 1981) initiated CGAS technology development in 2002. After over a decade of systematic research and industrial demonstration, it has evolved into a product series tailored to diverse industry needs. Gradually propelled by market forces, CGAS technology now drives industrial transformation and upgrades.

For instance, in the alumina industry—highly sensitive to fuel gas costs—CGAS technology commands two-thirds of the pulverized coal gasification market. Both of China's top two alumina producers have adopted CGAS to replace fixed-bed gasifiers, achieving annual cost savings of hundreds of millions yuan while resolving persistent environmental issues that plagued their operations for years.

"Within the industry, any mention of circulating fluidized bed technology inevitably points to the Institute of Engineering Thermophysics." — Prof. Che Defu, Xi'an Jiaotong University

Currently, CGAS technology has achieved 70 industrial installations, with 30 units already operational. This represents equipment output value of ¥3.3 billion and coal gas production value exceeding ¥10 billion. When fully deployed, it will replace 660 fixed-bed gasifiers, eliminating 2.6 million tonnes of wastewater contaminated with tar and phenols annually while utilizing over 9 million tonnes of low-rank pulverized coal. The complete technology package has also been exported to Indonesia, serving Belt and Road Initiative partner countries.

Yet this is merely the tip of the iceberg. Lü Qinggang emphasized that the market for retrofitting fixed-bed gasifiers remains vast, with less than 5% currently upgraded.

Advancing toward Large-Scale Coal Chemical Industry

Ammonia, a primary raw material for the fertilizer and organic chemical industries, boasts a global annual production exceeding 100 million tons. Historically, the synthesis of ammonia—a technology honored with three Nobel Prizes—represents a pinnacle of scientific achievement. Yet in reality, it remains an industry plagued by persistent pollution challenges, particularly in wastewater discharge.

"From the perspective of building a Beautiful China, the synthetic ammonia industry must transition to circulating fluidized bed technology." Qu Sijian emphasized, "China leads the world in scale across building materials, steel, and coking industries. Ultra-low emissions are an irreversible trend, and CGAS technology holds immense potential."

Given China's coal quality constraints, the key to clean and efficient utilization of low-rank pulverized coal lies in gasification technology, stated LV Qinggang. "This process converts solid coal into gaseous fuel for industrial gas and syngas applications." In 2017, approximately 800 million tons of coal underwent gasification in China, extensively deployed across steel, metallurgy, chemical engineering, building materials, and synthetic ammonia sectors. Projections indicate that by 2030, China will still require the conversion and utilization of around 800 million tons of coal annually.

Once entering the market, no matter how advanced the technology is, it must be practically applicable. To implement this transformation, the Institute of Engineering Thermophysics (IET) established a joint venture with local governments—Zhōngkē Héféi Coal Gasification Technology Co., Ltd. Supported by the CAS Hongguang Initiative, CGAS technology had captured 65.3% of China's market for clean industrial gas produced from pulverized coal by the end of 2018.

Professor Che Defu emphasized: 'Technology evolves perpetually—perfection isn't achieved overnight. We must persistently pursue technical excellence.'

Huang Congli, Party Secretary of the Institute of Engineering Thermophysics, stated: 'As a CAS-originated technology, our company must innovate in licensing and EPC models to scale its benefits nationwide, empowering local economies.'

For the CFB Laboratory, the mission is to redefine coal's narrative. 'China's journey toward national rejuvenation necessitates continued coal utilization,' LV Qinggang asserted. 'Our task is to enable industry to harness coal cleanly and efficiently—fortifying energy security while preserving blue skies over coal-fired industries.

(Source: Science China Daily)