At the start of 2020, the sudden outbreak of COVID-19 forced national enterprises to suspend operations. As pandemic pressures eased, many companies gradually resumed work. CAS Hefei Gasification Technology Co., Ltd.(hereinafter referred to as ZHGAS) thoroughly implemented President Xi Jinping’s directives on combating the pandemic and the State Council’s guidelines for coordinating epidemic control with economic and social development. Guided by the Institute of Engineering Thermophysics, Chinese Academy of Sciences (CAS), ZHGAS swiftly deployed measures to minimize pandemic impacts while maintaining stable operations.

By mid-2020, ZHGAS had activated key departmental plans. The design department organized personnel to advance documentation for ongoing projects, supported bid proposals with design blueprints, and refined management protocols based on annual performance reviews. The engineering department developed phased reopening plans, coordinated equipment procurement schedules, and prioritized safety training for post-pandemic operations. The commissioning team scheduled post-construction testing to meet project milestones and ensure system functionality. The administration completed pandemic response protocols, safety training materials, and procurement of protective supplies.

ZHGAS’s ability to swiftly coordinate cross-departmental efforts and maintain orderly operations reflects its robust management capabilities and execution strength, embodying the qualities of a stable and growing enterprise. As a rising star in the coal gasification industry, how has ZHGAS achieved sustained rapid growth?

Innovation-Driven Value Creation

Low-rank coal accounts for 55% of China’s proven coal reserves, and its clean, efficient utilization remains a national priority. Traditional fixed-bed gasification technology relies on high-quality lump coal, excluding low-rank coal. The CGAS (Circulating Fluidized Bed Coal Gasification) technology, developed by IET(Institute of Engineering Thermophysics), achieves efficient gasification of low-rank coal through high-concentration material circulation and energy recycling, significantly reducing operating costs. This addresses traditional challenges such as limited coal compatibility, high pollution, and high costs. Since its establishment, ZHGAS has invested over ¥30 million in R&D under national and provincial projects like the Hongguang Special Project advancing industrial demonstrations and commercialization of CGAS technologies, including fly ash melting and slag prevention, while integrating decades of operational experience to expand services like gasifier diagnostics and energy optimization.

CGAS technology exhibits extensive coal adaptability, suitable not only for low-rank coals such as lignite and long-flame coal, but also for challenging feedstocks like high-ash/high-sulfur/high-moisture coal (commonly termed "three-high" inferior coal), anthracite, lean coal, and pulverized coal with low reactivity. This flexibility enables users to reduce raw material costs through optimized coal selection while maintaining operational efficiency. By utilizing high-temperature preheated gasification agents, recovering syngas heat, and optimizing residual carbon furnace operations, the system’s energy efficiency and carbon conversion rate are significantly enhanced, achieving optimal energy performance. The process ensures ultra-low emissions: the syngas produced is free of tar and phenols, employs solid slag discharge and dry ash removal methods, and generates zero wastewater during production, delivering high environmental benefits. The CGAS (Circulating Fluidized Bed Coal Gasification) technology aligns precisely with market demands for coal gasification, addressing long-standing economic and environmental challenges faced by industry users. By spearheading technological and equipment advancements in coal-to-industrial gas production and coal-based synthetic ammonia, it has driven the rapid development of China’s clean coal gasification industry.

In 2019, ZHGAS was awarded the “National High-Tech Enterprise” certification by the Anhui Provincial Department of Science and Technology, the Anhui Provincial Department of Finance, and the Anhui Provincial Taxation Bureau. This recognition reinforces its commitment to independent innovation and R&D, providing a foundation for future technological advancements.

State-Owned Excellence, CAS Platform

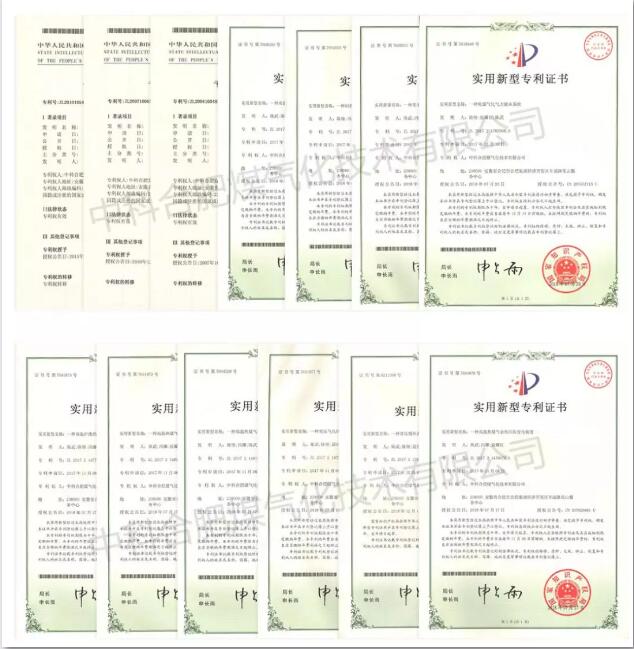

As a state-owned enterprise jointly established by IET (Institute of Engineering Thermophysics)and Hechao Economic Development Zone, ZHGAS leverages state-backed advantages such as stability, abundant resources, and strong risk resilience, supported by government funding, talent, and policies. ZHGAS is not only a National High-Tech Enterprise under IET but also the industrialization platform for the Hongguang Special Project "Industrialization of Circulating Fluidized Bed Coal Gasification Technology." IET’s leadership in CFB technology—with over 130 patents and dominant market share—provides robust R&D support. ZHGAS further drives technology upgrades and innovative solutions through IET’s platform.

Elite Team, Technical Expertise

Talent is the core driver of competitiveness. ZHGAS prioritizes talent development under the philosophy of "strengthening the enterprise through talent," refining recruitment strategies, career pathways, and training platforms. Its team includes:

7 professor-level senior engineers, 9 senior engineers, 40+ PhDs/master’s holders.

6 Class 1 constructors, 5 registered chemical engineers, 1 Registered Architect,2 Registered Structural Engineers,1 Registered Plumbing & Drainage Engineer,1 Registered HVAC Engineer,1 Registered Electrical Engineer,2 Registered Cost Engineers,2 Registered Power Engineers,10+ Senior/Intermediate Engineers,40+ Certified Technicians.

Core members possess over a decade of experience in CFB gasification R&D, pilot testing, and commercialization. ZHGAS boasts strong capabilities in professional R&D, technology commercialization, and engineering management. Additionally, it is supported by a specialized team for project commissioning and operational services. Beyond routine operational management training and support, the team provides full lifecycle technical support and system upgrades tailored to actual production conditions.

Market-Driven Industrialization

For technology-driven enterprises, whether they can closely align product R&D and technology breakthroughs with market applications remains a critical constraint on the growth of many mid-sized companies. As the lead entity of the Hongguang Initiative project 'Industrialization of Circulating Fluidized Bed Coal Gasification Technology,' ZHGAS has consistently anchored its R&D to industrial needs, focusing on practical production challenges. By applying CGAS technology across industries through technology integration, system optimization, engineering development, and market-oriented promotion, ZHGAS drives the translation of R&D achievements into industrial productivity.

ZHGAS has successfully implemented industrial solutions such as fixed-bed gasification section retrofits for coal-to-synthesis gas production and coal-to-clean gas conversion. Demonstration projects like the Xinjiang Yihua Gasification Project and Guizhou Hongsheng Synthetic Ammonia Retrofit are nearing trial operations, aiming to improve environmental standards in synthetic ammonia, fuel gas, and steel industries. In 2020, ZHGAS will expand CGAS to coking, alumina, and lime sectors, targeting projects with economic, social, and environmental benefits. Future plans focus on waste integration, hazardous waste treatment, and low-cost sludge disposal, driving sustainable development in clean energy and coal chemicals.